Fiddlehead Brewing Company, located just outside of Burlington, Vermont, is renowned for its delicious beer selection and its commitment to flavor, quality, the community, and the environment. Now Fiddlehead is doubling down on its environmental advocacy and reputation for a quality product by adding a drainage press directly into its canning line.

Humble beginnings

In 2011, Fiddlehead Brewing Co. opened a 3,000 square foot facility in scenic Shelburne, Vermont, just outside of the city of Burlington. In the decade since its establishment, the brewery has seen enormous success, expanding its physical footprint and production capacity to incorporate more production space and machinery. Now beer lovers benefit from its 35,000 square foot brewing space where 8,000 to 10,000 cases of delicious beer are filled each week! The brewery also has a tasting room at its original location for patrons to gather and sample the brew.

The 60-barrel brewhouse is home to a 24-head rotary filler that is capable of filling 250 cans each minute. This allows Fiddlehead to can and export beer to most of the northeastern United States, excluding only Maine. The Vermont brewery has high goals for 2022—they want to produce 90,000 barrels of their craft brew for distribution! The company has invested in machinery to streamline production and maximize its workforce, making this goal well within its grasp.

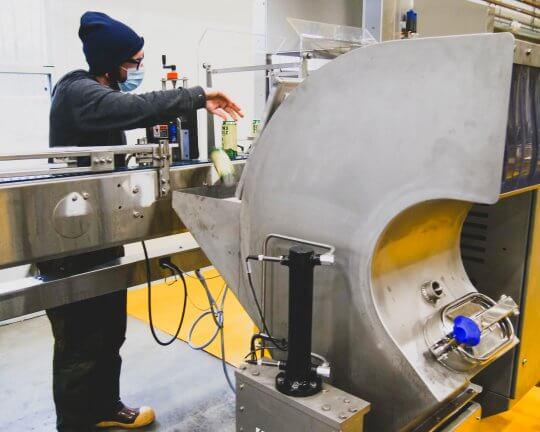

A canning line in operation

Quality control is key

During the canning process, occasionally cans are underfilled or otherwise “out of spec.” To meet the brewery’s quality control standards, these cans must be removed from the production line. The rejected product must be destroyed to ensure that only the very best product leaves the facility for distribution to bars and stores. Historically the company had employees manually opening and pouring out beer cans for a couple of hours each shift. This work, while necessary, was both monotonous and impractical.

“Efficiency is important, but we also want our employees to enjoy the work they do. Pouring cans down the drain was not enjoyable, and we knew there had to be a better option for this process.”

Jon Moorer, Production Manager of Fiddlehead Brewing Company

Learn more about WEIMA drainage presses!

Click here!

Partners in sustainability

That’s when Fiddlehead reached out to WEIMA. The WEIMA E.200 drainage press installation now gives the brewery more flexibility while freeing up its employees to do more meaningful and essential tasks.

The E.200 drainage press was delivered in late 2021 and was quickly and easily integrated into Fiddlehead’s pre-existing canning line. The out-of-spec rejects are now automatically ejected from the conveyor, allowing the rejected cans to fall directly into the hopper of the E.200. The aluminum cans are then hydraulically pressed into round discs, allowing the liquid contents to simultaneously drain from the faulty cans.

The addition of the E.200 to the canning line cleared the employees to do more meaningful tasks while ensuring that only the best beer makes it to the customer’s glass. The ejected discs of compressed aluminum save space on the production floor and make recycling the valuable metal more manageable and profitable.

Compressed aluminum cans are easy to store and recycle.

Contact

Contact

Sign-up for our newsletter

Additional Information

About WEIMA

More than 40,000 machines sold worldwide! WEIMA has been manufacturing robust shredders and briquetting presses for the disposal and processing of all types of waste for more than four decades. Our machines include single-shaft shredders, four-shaft shredders, cutting mills and briquette presses. The popular blood orange machines are used in the wood, plastics, paper, metal and waste-to-energy industries.

Made in Germany. Built for the world.

Shredders and briquette presses from WEIMA are exclusively made in Germany and come from production plants in Saxony-Anhalt and Baden-Wuerttemberg. Every year, more than 300 employees work on around 1,200 customer solutions from around the globe. We have long-standing sales and service locations in the USA, Poland, India and China. More than 80 representatives supplement this global presence.

Newsletter

Sign-up for our newsletter and get all the latest updates in your mailbox

Sign-up for our newsletter