C 170

The C 170 is particularly suitable for small and medium-sized plants whose required throughput rate does not exceed 50-80 kg/h or 200 to 400 kg/day. Virtually any suitable material can be briquetted, such as wood, polystyrene, foams, paper or biomass. All machines are available as left-hand or right-hand versions. Mounted on a stable base frame, this machine ensures quick installation and makes mobile use possible.

C Series briquetting presses offer a large capacity for material to be compressed. Depending on the space requirements, the press unit and the hydraulic unit can be flexibly installed to the right or left of the hopper. The agitator and the material screw conveyor are located at the bottom of the hopper. If required, the hopper can be equipped with a fill level monitoring system which automatically switches off the briquette press as soon as the material quantity falls below a defined level.

The screw conveyor below the feed hopper transports a defined quantity of material into the filling tower. There, vertical pre-compaction takes place, with a slide pressing the material into the press sleeve below. A particularly solid briquette can then be produced after the subsequent clamp compaction.

The compact hydraulic unit is located directly next to the feed hopper. It is temperature controlled. The pump motor is designed for long service life.

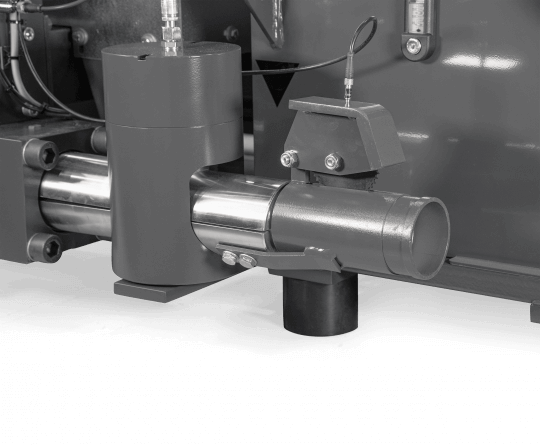

The extremely wear-resistant, chrome-plated pressing clamp is surrounded by a hydraulic closing cylinder. It holds the briquette produced by the pressing cylinder during pressing. For this purpose, both halves of the clamp are closed and opened again during discharge.

A C 150 briquetting press compresses MDF dust into solid briquettes – naturally without the addition of binders.

The agitator installed at the bottom of the feed hopper ensures a constant material feed to the screw conveyor. The continuous material circulation also prevents material bridging and breaks up lumps.

No frills – the most important things at a glance. The built-in Siemens PLC control is optimally adapted to the briquetting process. Various settings can be conveniently adjusted to the desired application. All control cabinets are designed in-house and built in our German production facilities using international standard parts.

To ensure that the briquette length remains constant even with changing materials, briquetting presses of the C series come standard with an electromechanical briquette length monitor with proximity switch. This is located directly in front of the clamp on the briquette discharge pipe.

Filtered paper dust is turned into highly compressed briquettes with a diameter of 50 mm by means of a C 150 briquetting press.

WEIMA's standard pressing chamber wear sleeves are hardened. Optionally, they are made of tool steel. In both cases, increased wear of the press chamber is effectively prevented – especially with abrasive materials containing sand, soil, or metal chips. Instead of replacing the entire press block when wear occurs, only the significantly less expensive pressing chamber needs to be replaced. This saves labor, time, and costs – maintenance is significantly simplified.

All installed cylinders are have stroke cushioning and come equipped with a bolted lock. This guarantees easy access for maintenance or modifications.

The material is conveyed in metered quantities from the hopper to the pressing unit by means of a screw conveyor. For this purpose, a precise quantity required to produce a single briquette is defined electromechanically via the screw speed and running time. Compared to conventional horizontal pushers, this efficiently avoids material bridging or clogging of the feed channel.

With the help of hydraulic pressure, handy briquettes are produced from shredded straw and corn waste.

The company has been manufacturing high-quality wooden garden furniture in Nantwich (United Kingdom) since 1926. Waste wood accumulating up to…

Read more

CNC World, a British vendor of CNC machines, has recently started to process its wood waste mechanically in order to heat the workshop in a resource-saving manner.

Read more